Hydroelectric power generation involves the storage of a hydraulic fluid, normally water, conversion of the hydraulic energy of the fluid into mechanical energy in a hydraulic turbine, and conversion of the mechanical energy to electrical energy in an electric generator.

The first hydroelectric power plants came into service in the 1880s and now comprise approximately 22% (660 GW) of the world’s installed generation capacity of 3000 GW. Hydroelectricity is an important source of renewable energy and provides significant flexibility in base loading, peaking, and energy storage applications. While initial capital costs are high, the inherent simplicity of hydroelectric plants, coupled with their low operating and maintenance costs, long service life, and high reliability, make them a very cost-effective and flexible source of electricity generation. Especially valuable is their operating characteristic of fast response for start-up, loading, unloading, and following of system load variations. Other useful features include their ability to start without the availability of power system voltage (“black start capability”), ability to transfer rapidly from generation mode to synchronous condenser mode, and pumped storage application.

Hydroelectric plants are located in geographic areas where they will make economic use of hydraulic energy sources. Hydraulic energy is available wherever there is a flow of liquid and head. Head represents potential energy and is the vertical distance through which the fluid falls in the energy conversion process. The majority of sites utilize the head developed by fresh water; however, other liquids such as salt water and treated sewage have been utilized. The siting of a prospective hydroelectric plant requires careful evaluation of technical, economic, environmental, and social factors. A significant portion of the project cost may be required for mitigation of environmental effects on fish and wildlife and re-location of infrastructure and population from flood plains.

There are three main types of hydroelectric plant arrangements, classified according to the method of controlling the hydraulic flow at the site:

1.Run-of-the-river plants, having small amounts of water storage and thus little control of the flow through the plant.

2.Storage plants, having the ability to store water and thus control the flow through the plant on a daily or seasonal basis.

3.Pumped storage plants, in which the direction of rotation of the turbines is reversed during off- peak hours, pumping water from a lower reservoir to an upper reservoir, thus “storing energy” for later production of electricity during peak hours.

The type of turbine selected for a particular application is influenced by the head and flow rate. There are two classifications of hydraulic turbines: impulse and reaction.

The impulse turbine is used for high heads — approximately 300 m or greater. High-velocity jets of water strike spoon-shaped buckets on the runner which is at atmospheric pressure. Impulse turbines may be mounted horizontally or vertically and include perpendicular jets (known as a Pelton type), diagonal jets (known as a Turgo type) or cross-flow types.

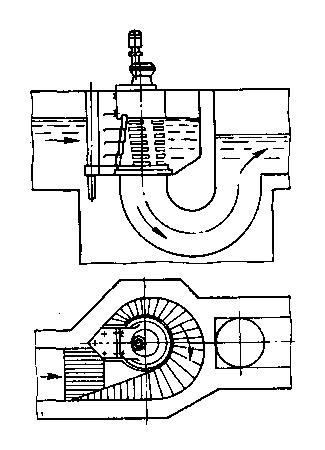

In a reaction turbine, the water passes from a spiral casing through stationary radial guide vanes, through control gates and onto the runner blades at pressures above atmospheric. There are two categories of reaction turbine — Francis and propeller. In the Francis turbine, installed at heads up to approximately 360 m, the water impacts the runner blades tangentially and exits axially. The propeller turbine uses a propeller-type runner and is used at low heads — below approximately 45 m. The propeller runner may use fixed blades or variable pitch blades (known as a Kaplan or double regulated type) which allows control of the blade angle to maximize turbine efficiency at various hydraulic heads and generation levels. Francis and propeller turbines may also be arranged in slant, tubular, bulb, and rim generator configurations.

Water discharged from the turbine is directed into a draft tube where it exits to a tailrace channel, lower reservoir, or directly to the river.

1. Read and translate the text.

2. Find the English equivalents in the text:

Режим синхронной компенсации, возможность автономного пуска, система гидроаккумулирования энергии, русловая ГЭС, гидроаккумулирующая ГЭС, насосная гидроаккумулирующая ГЭС, активная (свободноструйная) турбина, реактивная (напорноструйная) гидротурбина, рабочее колесо гидротурбины, направляющая лопатка, радиально-осевая реактивная гидротурбина.

3. Read the text again and number the points of the plan in the correct order.

1) Hydroelectric plant’s location.

2) The main types of hydroelectric plants.

3) Two types of turbines for hydroelectric plants.

4) The importance of hydroelectric power generation.

5) The history of hydroelectric power generation.

6) The difference between hydroelectric plant turbines.

4. Put questions to the underlined words.

1) Hydroelectric power generation involves the storage of water, conversion of the hydraulic energy into mechanical energy and conversion of the mechanical energy to electrical energy in an electric generator.

2) There arethree main types of hydroelectric plant arrangements, classified according to the method of controlling the hydraulic flow.

3) Water discharged from the turbine is directed into a draft tube.

4) The type of turbine selected for a particular application is influenced by the head and flow rate.

5) The propeller turbine uses a propeller-type runner.

5. Find the antonyms.

| output

| unguided

|

| isolated

| high

|

| controllable

| alternating current

|

| majority

| input

|

| synchronous

| asynchronous

|

| low

| vertical

|

| horizontal

| minority

|

| direct current

| bound, linked

|

6. Match the words from the text with their corresponding definitions.

| start-up

| the state or quality of being available

|

| loading

| relating to or forming an axis

|

| availability

| include as a necessary part

|

| evaluation

| setting in operation

|

| involve

| of or relating to a tangent;

|

| tangential

| the act or process of evaluating or establishing the value or amount

|

| axial

| the amount of work a person or machine is expected to do

|

7. Write down the differences:

| Run-of-the-river plant

| Storage plant

| Pumped storage plant

|

|

|

|

|

8. Make an oral summary of the text.

TEXT 5. Generator

Synchronous generators and induction generators are used to convert the mechanical energy output of the turbine to electrical energy. Induction generators are used in small hydroelectric applications (less than 5 MVA) due to their lower cost which results from elimination of the exciter, voltage regulator, and synchronizer associated with synchronous generators. The induction generator draws its excitation current from the electrical system and thus cannot be used in an isolated power system. Also, it cannot provide controllable reactive power or voltage control and thus its application is relatively limited.

The majority of hydroelectric installations utilize salient pole synchronous generators. Salient pole machines are used because the hydraulic turbine operates at low speeds, requiring a relatively large number of field poles to produce the rated frequency. A rotor with salient poles is mechanically better suited for low-speed operation, compared to round rotor machines which are applied in horizontal axis high-speed turbo-generators.

Generally, hydroelectric generators are rated on a continuous-duty basis to deliver net kVA output at a rated speed, frequency, voltage, and power factor and under specified service conditions including the temperature of the cooling medium (air or direct water). Industry standards specify the allowable temperature rise of generator components (above the coolant temperature) that are dependent on the voltage rating and class of insulation of the windings. Standards also provide guidance on short circuit capabilities and continuous and short-time current unbalance requirements.

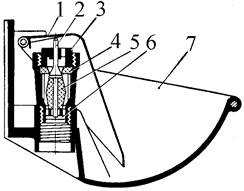

Synchronous generators require direct current field excitation to the rotor, provided by the excitation system.

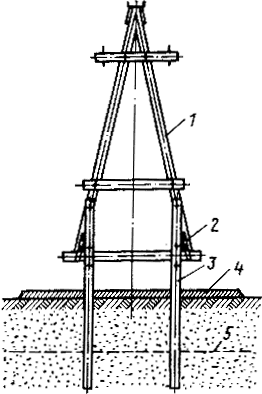

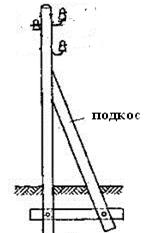

While the generator may be vertical or horizontal, the majority of new installations are vertical. The basic components of a vertical generator are the stator (frame, magnetic core, and windings), rotor (shaft, thrust block, spider, rim, and field poles with windings), thrust bearing, one or two guide bearings, upper and lower brackets for the support of bearings and other components, and sole plates which are bolted to the foundation. Other components may include a direct connected exciter, speed signal generator, rotor brakes, rotor jacks, and ventilation systems with surface air coolers.

The stator core is composed of stacked steel laminations attached to the stator frame. The stator winding may consist of single turn or multi-turn coils or half-turn bars, connected in series to form a three phase circuit. Double layer windings, consisting of two coils per slot, are most common. One or more circuits are connected in parallel to form a complete phase winding. The stator winding is normally connected in wye configuration, with the neutral grounded through one of a number of alternative methods which depend on the amount of phase-to-ground fault current that is permitted to flow. Generator output voltages range from approximately 480 VAC to 22 kVACline-to-line, depending on the MVA rating of the unit. Temperature detectors are installed between coils in a number of stator slots.

The rotor is normally comprised of a spider attached to the shaft, a rim constructed of solid steel or laminated rings, and field poles attached to the rim. The rotor construction will vary significantly depending on the shaft and bearing system, unit speed, ventilation type, rotor dimensions, and characteristics of the driving hydraulic turbine. Damper windings or amortisseurs in the form of copper or brass rods are embedded in the pole faces, for damping rotor speed oscillations.

The thrust bearing supports the mass of both the generator and turbine plus the hydraulic thrust imposed on the turbine runner and is located either above the rotor (“suspended unit”) or below the rotor (“umbrella unit”). Thrust bearings are constructed of oil-lubricated, segmented, babbit-lined shoes. One or two oil lubricated generator guide bearings are used to restrain the radial movement of the shaft.

Fire protection systems are normally installed to detect combustion products in the generator enclosure, initiate rapid de-energization of the generator and release extinguishing material. Carbon dioxide and water are commonly used as the fire quenching medium.

Excessive unit vibrations may result from mechanical or magnetic unbalance. Vibration monitoring devices such as proximity probes to detect shaft run-out are provided to initiate alarms and unit shutdown.

The choice of generator inertia is an important consideration in the design of a hydroelectric plant. The speed rise of the turbine-generator unit under load rejection conditions, caused by the instantaneous disconnection of electrical load, is inversely proportional to the combined inertia of the generator and turbine. Turbine inertia is normally about 5% of the generator inertia. During design of the plant, unit inertia, effective wicket gate or nozzle closing and opening times, and penstock dimensions are optimized to control the pressure fluctuations in the penstock and speed variations of the turbine-generator during load rejection and load acceptance. Speed variations may be reduced by increasing the generator inertia at added cost. Inertia can be added by increasing the mass of the generator, adjusting the rotor diameter, or by adding a flywheel. The unit inertia also has a significant effect on the transient stability of the electrical system, as this factor influences the rate at which energy can be moved in or out of the generator to control the rotor angle acceleration during system fault conditions.

1. Read and translate the text.

2. Read the text again and make a plan in the form of questions.

3. Read and decide if the following statements are true (T) or false (F).

1) Synchronous generators and induction generators are used to convert electrical energy into mechanical energy.

2) Salient pole machines are used because the hydraulic turbine operates at high speeds.

3) Industry standards specify the allowable temperature drop of generator components.

4) Synchronous generators required direct current field excitation to the rotor.

5) The stator core is composed of stacked steel laminations attached to the stator winding.

4. Match the words from the text with their corresponding definitions.

| convert

| to increase the activity of; stimulate

|

| excite

| a long slender body connected to the head of an arrow, a deep passage

|

| salient

| change in character, condition or use

|

| shaft

| standing out from the rest; most noticeable or important

|

| solid

| having shape and hardness, not liquid or gaseous

|

5. Complete the table below using a dictionary.

| Verb

| Noun (idea)

| Noun (person)

| Adjective

|

| -

| excitation

| -

| -

|

| describe

| -

| -

| -

|

| generate

| -

| -

| -

|

| -

| winding

| -

| -

|

| -

| connection

| -

| -

|

| detect

| -

| -

| -

|

6. Discuss different types of generators with your partner. Use your own plan to the text.