The choice of transmitting and distributing electric power through underground or overhead systems requires consideration of economical, technical, and environmental issues. Underground systems have traditionally been favoured when distributing electric power to densely populated areas and when reliability or aesthetics is important. Underground distribution systems provide superior reliability because they are not exposed to wind, lightning, vandalism, or vehicle damage. These factors are the main contributors to failures of overhead electric power distribution systems. When designed and installed properly, underground distribution systems also require less preventive maintenance. The main disadvantage of underground transmission and distribution systems as compared with overhead lines is its higher cost. Underground transmission and distribution of electric power is done through the use of insulated power cables. Cable designs vary widely depending on many factors such as voltage, power rating, application, etc.; however, all cables have certain common components.

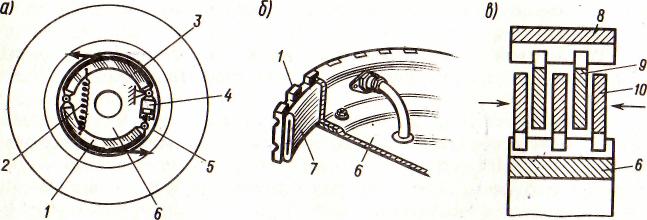

The basic function of an insulated power cable is to transmit electric power at a predetermined current and voltage. A typical single-core insulated power cable consists of a copper or aluminum conductor and several layers of insulation. The constructional design of power cables is more complex for cables designed for higher voltages. Power insulated cables are designed to endure different types of stresses such as electrical stress caused by the rated voltage and by transient overvoltages, mechanical stress due to tension and compression during the installation, thermal stress produced during normal operation, and chemical stress caused by the reaction with the environment that may occur when the cable is installed in aggressive soils or in the presence of some chemicals. An insulated power cable typically consists of the following elements: a) central conductor, through which the electric current flows, b) the insulation, which withstands the applied voltage to the ground, c) shielding, consisting of a semiconductor shield that uniformly distributes the electric field around the insulation, d) a metallic sheath that provides a reference for the voltage and a path for the return and short-circuit currents, and e) an external cover that provides mechanical protection.

The conductor of a typical power cable is made of copper or aluminum. A single-core cable with a concentric configuration consists of a single central wire around which concentric layers of wire are built. An alternative configuration is the shaped compact single-core cable. The compacted cable is obtained by passing the cable through compacting machines to obtain its form. Because of compacting ratios of 85 to 90%, more current capacity per unit of transversal section is achieved with compact cable, and they are therefore sometimes preferred over regular concentric cables.

Presently, synthetic materials are preferred for insulation of cables. The chemical composition of such materials can be altered to produce polymers with specific chemical, electrical, and mechanical properties. Although the list of materials used as cable insulation is extensive, ethylene propylene (EP or EPR) and cross-linked polyethylene (XLP or XLPE) are by far the most popular. EP and XLP insulation have similar insulating characteristics and expected long life under the same operational conditions.

In a typical high-voltage cable, two layers of semiconductor material surround the metallic core. The first layer, placed directly around the conductor, has the following purposes: 1) to distribute the electric field uniformly around the conductor, 2) to prevent the formation of ionized voids in the conductor, 3) to dampen impulse currents travelling over the conductor surface. The second layer of semiconductor material is placed around the first insulating layer and has the following purposes: 1) to reduce the surface voltage to zero, 2) to confine the electric field to the insulation, eliminating tangential stresses, 3) to offer a direct path to ground for short-circuit current if the shield is grounded.

The metallic sheath surrounding insulated cables serves several purposes: as an electrostatic shield, as a ground fault current conductor, and as a neutral wire. The metallic sheath designed for electrostatic purpose should be made of non-magnetic tape or non-magnetic wires. Copper is usually used for these sheaths. When properly grounded, this sheath provides a path for short-circuit current. With appropriate dimensions, the metallic sheath can be used as a system neutral, as in residential distribution cables where single-phase transformers are common. When single-core cables are used in three-phase systems, the grounded sheath provides a path for unbalanced currents. When high-voltage underground cables require some type of moisture insulating barrier, a metallic pipe surrounds the current-carrying cable. The materials most commonly used as moisture barriers are lead and aluminum. The electric currents carried by the high-voltage cable will induce a voltage in the metallic shield that surrounds the conductor, and in the shields of other surrounding cables. These induced voltages, in turn, will generate an induced current flow with its associated heat losses. In the case of steel shields, the losses will include magnetization and hysteresis losses.

The purpose of the external layer in insulated power cables is to provide mechanical protection against the environment during the installation and operation of the power cable. Currently, materials commonly used as the external layer for extruded power cables include PVC and polyethylene of low and high density. These materials are used for their ability to withstand the cable operating temperature, their resistance to excessive degradation when in contact with some chemicals typical of some operating environments, and their excellent mechanical properties for undergoing stresses during transportation, or compression and tension during installation and operation.

1. Read and translate the text.

2. Read the text again and number the points of the plan in the correct order.

1). External Layer

2). Semiconductor Shield

3). Typical Cable Description

4). Underground Distribution Systems Advantage

5). Conductor

6). Metallic Sheath

7). Insulation

3. Answer the following questions to the text.

1). Can you name some advantages of distributing electric power through underground?

2). What does a typical insulated power cable consist of?

3). What is the function of the first layer of a semiconducting shield?

4). What is the metallic sheath used for?

5). When do induced voltages occur?

4. Complete the table. Use a dictionary if necessary. Do not fill in the shaded boxes.

| Noun

| Verb

| Adjective

| Adverb

|

|

|

| specific

|

|

|

| to alternate

|

|

|

| ground

|

|

|

|

|

| to prevent

|

|

|

|

| to eliminate

|

|

|

|

|

| dense

|

|

5. Match the beginning of each sentence with the most appropriate ending.

| 1). There are two widely used circuit configurations…

| a). with telephone, gas, water, or other facilities.

|

| 2). In some instances, power cables can be installed…

| b). it is necessary to diagnose the cause of the fault.

|

| 3). Accidental contact and aging account…

| c). preferred in underground systems for residential areas.

|

| 4). Once the existence of the fault is assured…

| d).are based on travelling waves theory

|

| 5). Most modern instruments used to pinpoint faults…

| e). for more than 50% of all faults in underground cables.

|

6. Think of underground distribution systems. Explain their electric power distribution requirements. What type of insulation is required and why?